|

ROSCHEN

|

Exploration Core Drilling Wireline Core Barrel BQ HQ NQ PQ with Long Life

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Exploration Core Drilling Wireline Core Barrel BQ HQ NQ PQ with Long Life

<

Exploration Core Drilling Wireline Core Barrel BQ HQ NQ PQ with Long Life

Quick Detail:

Core Barrel

Craelius Core Barrel

Longyear Core Barrel

Boart Longyear Core Barrel

Sandvik Core Barrel

Atlas Copco Core Barrel

Wireline Drilling Core Barrel BQ HQ NQ PQ

Wire-line core drilling tools can lift core from drill rods without picking up coring system.A complete set of wire-line drill tools include:Core barrel assembly, overshot assembly, drill rods, holding dog, hoisting plug, circle wrench etc.It has some advantages such as high penetration rate, high core recovery ratio, long bit life and lower labour intensity.The advantages can get more clear with the increasing of drill hole depth.

Roschen could supply BQ Core Barrel, NQ Core Barrel, HQ Core Barrel, PQ Core Barrels

Description:

|

Features: |

Longer life, high-resistance wear |

Material: |

Metal, high resistance steel |

|

Type: |

Q, Wireline, Double Tube, Metric, WT, NMLC, HMLC, WM, WG, T2, T6 series |

Use: |

Mineral Exploration, Mineral Exploration |

|

Product Name: |

Core Barrel |

Crown Height: |

5ft/1.5M, 10ft/3M |

Applications:

Excore head assembly

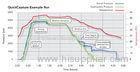

Part of the Excore product solutions, our new line of high performance head assemblies are now available in DCMA size B,N and H, for both surface and pump-in applications. The simple to use, easy to repair and maintain head will provide drillers with what they need to retrieve core, shift after shift. The secure latching and the mechanical piston that locks the core barrel head in the locking coupling is extremely strong and will secure the inner tube within the locking coupling, even in high back pressure bore holes.

Along with a primary landing indication, a secondary latching indication system will let the driller know, not only if he has landed but also if the latches are not fully engaged; signalling that there is a problem in the core barrel and that further actions are needed.

The new Excore head assembly is designed to reduce inventory with its ability to convert from a surface system to a pump-in system for drillers who work in both surface and underground operations. Its improved latching system reduces the chance of mis-latching complications, which will increase productivity and reduce chances of downtime.

Excore "Auto Safe" Overshot

We are very proud to offer drilling contractors, with the drilling crews' safety in mind, this innovative and safer overshot; The new Excore series, "Auto Safe" EX Overshot. The safety mechanism of this overshot, unlike competing products, does not require direct intervention from the drilling crew to engage. This means, that the crew cannot forget to engage the safety mechanism as it is automatic and while pulling the inner tube, they do not need to stop the process to retrieve the core. As a result, operators are confident and have peace of mind with one less process to worry about. The simplified process increases the speed of the overall cycle and increases productivity levels.

Surface Core Barrels:

Applying advanced technology to today's core drilling tools and processes is a science in itself. And it's one in which Roschen Exploration Products engineers have taken a leadership role. Conventional or wireline drilling, Roschen Exploration Products drill rods, core barrels and casings are being constantly upgraded to exceed the expectations of today's diamond drilling contractors and mining companies around the globe.

Underground Core Barrel:

Designed to meet the most stringent drilling requirements, Roschen Exploration Products pump in head assemblies and overshots are made from top quality, field proven components, and allow you to easily upgrade your existing underground wireline in-hole tools configuration.

Compatible and interchangeable by design, the head assembly features a precision manufactured, three-piece latch body design, complete with a reversible and replaceable landing shoulder.

Inside out, Roschen Exploration Products core barrels and other ITH tools and accessories are designed and manufactured to improve core drilling productivity. Start saving right away when you integrate and upgrade your system today!

Conventional Core Barrels:

Designed to meet the most stringent drilling requirements, Roschen Exploration Products conventional Core Barrels' are made from top quality, field proven components, and allow you to easily upgrade your existing conventional In-hole tools configuration.

Conventional core barrels produce a larger core diameter compared to the equivalent wireline nominal size. Their rugged construction and design features ensure optimization of productivity in applications where the use of a wireline system is not practical or cost effective.

Core barrel introdution:

Used in loose, broken stratigraphic or coal extraction and protect rock (mine) heart of drilling tools.

Double core tube and tube has outer pipe, rinses through joint between the internal and external tube water flow to the bottom of the hole, protecting cores from rinses washouts. Double core tube has double motion and single movement two kinds. Double motion and core tube is internal and external core tube following bit and drill stem rotation, it in no serious loose or broken strata.

Single movement double core tube internal and external tube has bearing isolation, pipe outer pipe driven only pick up bit rotation, and broken rock tube does not rotate, avoid to core friction, vibration, etc., with mechanical damage, so it in serious loose fractured formations.these, can be well protected cores.

Use double deck core tube take core, bits need to use wall thickness of the alloy drill or diamond bits.

Due to the rock drill contact surface area increased and the lip use double deck core tube than ordinary core tube drilling efficiency to reduce. In the ledge, coal, in order to guarantee rock (mineral) heart take rate, rules must be use double deck core tube coring. More complex double core tube, except to finish single movement, in addition, aluminum, steel tube placed plastic or qualitative buckled half close tube, have a better protection of the core role.

Double core tube card broken cores and seal block within the next port, the core tube by the drill is placed in the core card fault device (fern, card spring, claw reed, etc.) to finish.

Specifications:

Core Barrels

Craelius Core Barrel

Longyear Core Barrel

Boart Longyear Core Barrel

Sandvik Core Barrel

Atlas Copco Core Barrel

Wireline Core Barrel

AQTK Core Barrel

BQ Core Barrel

NQ Core Barrel

HQ Core Barrel

PQ Core Barrel

NMLC Core Barrel

HMLC Core Barrel

NWG Core Barrel

HWG Core Barrel

AQWL Core Barrel

BQWL Core Barrel

NQWL Core Barrel

HQWL Core Barrel